EQUIPMENTS & FACILITIES

We know the power of quality

Vertical & Horizontal Slitting Machine (Automatic)

Consists of three main parts: unwind, slitting & rewound work processes.

Vertical & Horizontal of slitting direction before being rewound into cores of various widths.

Appropriate cutting for Expanded Polyethylene(EPE) or Cross-Linked Polyethylene (XPE) foams in rolls: Sheets or Planks into small size possibilities.

Installation: 1 unit

Vertical & Horizontal Slitting Machine (Automatic)

Consists of three main parts: unwind, slitting & rewound work processes.

Vertical & Horizontal of slitting direction before being rewound into cores of various widths.

Appropriate cutting for Expanded Polyethylene(EPE) or Cross-Linked Polyethylene (XPE) foams in rolls: Sheets or Planks into small size possibilities.

Installation: 1 unit

Foam Cutting Bandsaw Machine

Designed to cut sheets of material from larger block: insulation materials, rigid materials and other low or medium density materials.

Potentially to cut high-density foam to size of projects with inexpensive tool.

Installation: 2 units

Foam Cutting Bandsaw Machine

Designed to cut sheets of material from larger block: insulation materials, rigid materials and other low or medium density materials.

Potentially to cut high-density foam to size of projects with inexpensive tool.

Installation: 2 units

Precision Hydraulic Die-Cutting Machine

Auto-balance structure of double-cylinder, four-column and self-balance connecting rod, ensure equal pressure during cutting.

Suitable for Die-cut foams, suitcases, casing, cleaning sponger & etc.

Stroke adjustment device, makes stroke simple and correct with cutting die, board and materials.

Installation: 3 units

Precision Hydraulic Die-Cutting Machine

Auto-balance structure of double-cylinder, four-column and self-balance connecting rod, ensure equal pressure during cutting.

Suitable for Die-cut foams, suitcases, casing, cleaning sponger & etc.

Stroke adjustment device, makes stroke simple and correct with cutting die, board and materials.

Installation: 3 units

Hot Air Laminating Machine

Performing melts the surface of Polyurethane(PU) or Polyethylene(PE) foams for an adhesive produced from the pre-cut materials.

Advantage of the machine is to protect and enhance the quality of the material which is being laminated.

Lamination increases the durability of materials, allowing to withstand for frequent usage.

Installation: 1 unit

Hot Air Laminating Machine

Performing melts the surface of Polyurethane(PU) or Polyethylene(PE) foams for an adhesive produced from the pre-cut materials.

Advantage of the machine is to protect and enhance the quality of the material which is being laminated.

Lamination increases the durability of materials, allowing to withstand for frequent usage.

Installation: 1 unit

Hot Plate Welding Machine

Generate heat to melts the foams surface, so that those foams can be joined even in layers.

A kind of heat sealing process that applies heat and pressure to multiple materials pieces, either through a rotary press or manually in order to form a permanent seam in-between.

Welding can establishes strong, durable and permanent joint links results in a great finish.

Installation: 1 unit

Hot Plate Welding Machine

Generate heat to melts the foams surface, so that those foams can be joined even in layers.

A kind of heat sealing process that applies heat and pressure to multiple materials pieces, either through a rotary press or manually in order to form a permanent seam in-between.

Welding can establishes strong, durable and permanent joint links results in a great finish.

Installation: 1 unit

Convoluted Machine

Commonly referred to “egg crate foam”, traditional convoluted foam is a ridged design consisting of peaks and valleys.

With machine rollers, foam craft can turn one solid piece of foam into two pieces which share material, allowing for surface softness and material savings.

Provides improved comfort and measurable pressure relief in bedding and seating applications.

Installation: 1 unit

Convoluted Machine

Commonly referred to “egg crate foam”, traditional convoluted foam is a ridged design consisting of peaks and valleys.

With machine rollers, foam craft can turn one solid piece of foam into two pieces which share material, allowing for surface softness and material savings.

Provides improved comfort and measurable pressure relief in bedding and seating applications.

Installation: 1 unit

Sliding Table Wood Cutting Machine

Contain a vary of chainsaws for cutting a plywood or parts in many different of sizes.

Flawless cutting accuracy and excels at intricate design to support the require works.

Wide range of uses in wood processing and perform a clean cut results for longitudinal or cross-cuts in softwood and hardwood.

Installation: 1 unit

Sliding Table Wood Cutting Machine

Contain a vary of chainsaws for cutting a plywood or parts in many different of sizes.

Flawless cutting accuracy and excels at intricate design to support the require works.

Wide range of uses in wood processing and perform a clean cut results for longitudinal or cross-cuts in softwood and hardwood.

Installation: 1 unit

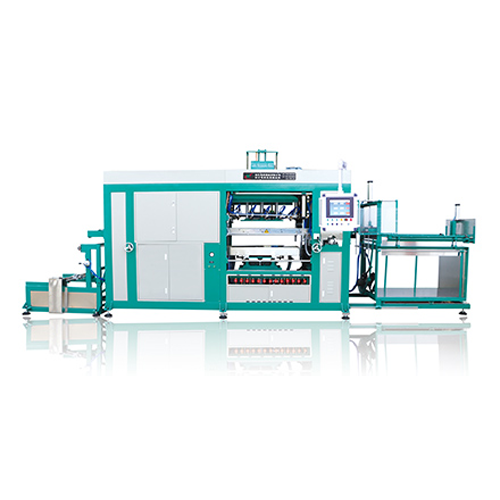

NF1250C Intelligent Automatic High Speed Plastic Forming Machine

Can blister all kinds of films (PVC, PP, PS, PET, etc.) into plastic covers of different shapes to support various parts packaging.

Functioning for casting involves introducing a liquefied plastic into a mold and allowing it to solidify. In contrast to molding and extrusion, casting relies on atmospheric pressure to fill the mold rather than using significant force to push the plastic into the mold cavity.

Advantages for high efficiency outputs, complex part design, enhance strength, flexibility-material and color, repeatability, reduce waste and etc.

Installation: 1 unit

NF1250C Intelligent Automatic High Speed Plastic Forming Machine

Can blister all kinds of films (PVC, PP, PS, PET, etc.) into plastic covers of different shapes to support various parts packaging.

Functioning for casting involves introducing a liquefied plastic into a mold and allowing it to solidify. In contrast to molding and extrusion, casting relies on atmospheric pressure to fill the mold rather than using significant force to push the plastic into the mold cavity.

Advantages for high efficiency outputs, complex part design, enhance strength, flexibility-material and color, repeatability, reduce waste and etc.

Installation: 1 unit